What Should I Look Into Prior To Buying An Email List Of Hematologists? When purchasing a hematologist email list, you must concentrate on a number of crucial aspects to ensure that the list you purchase is accurate, efficient, legally compliant, and appropriate to your goals in marketing. These are the most crucial considerations to consider. Qual

30 Free Reasons For Choosing Devil666 Slot Sites

Top 10 Tips To Help You Choose The Most Suitable Game For Your Online Betting Platform In Indonesia When choosing Devil666 Indonesian online betting platforms the variety of games available is an important aspect that will significantly improve your gambling experience. An extensive selection of games will give you a greater range of betting choice

30 New Suggestions For Choosing 7raja Togel Sites

Top 10 Tips On Regulation And Licensing For 7 Raja Togel Indonesian Online Betting Platforms Understanding the 7 Raja Togel Indonesian regulation and licensing landscape can help you ensure that your online betting platform is secure and legal. Here are 10 important tips to ensure that 7raja Togel Indonesian online betting sites are in compliance w

30 Great Tips For Deciding On ASIAN 2 BET Websites

Top 10 Suggestions For ASIAN2BET Login Indonesian Betting Websites Regarding Payment Options Payment options should be considered when evaluating ASIAN 2 BET Indonesian websites for online betting. Payment methods such as access, security, and ease of use can impact the overall experience of betting. Here are the top ten tips to evaluate ASIAN 2 BE

30 Great Suggestions For Picking TAJIR4D Websites

Top 10 Tips On Game Variety For tajir4d rtp Indonesian Online Betting Platforms The variety of games available is crucial when selecting tajir4d togel Indonesian betting sites online. This can improve your gambling experience. A wide range of games ensures that you have access to many betting options and can enjoy an exciting and diverse experience

Tatyana Ali Then & Now!

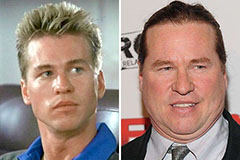

Tatyana Ali Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!